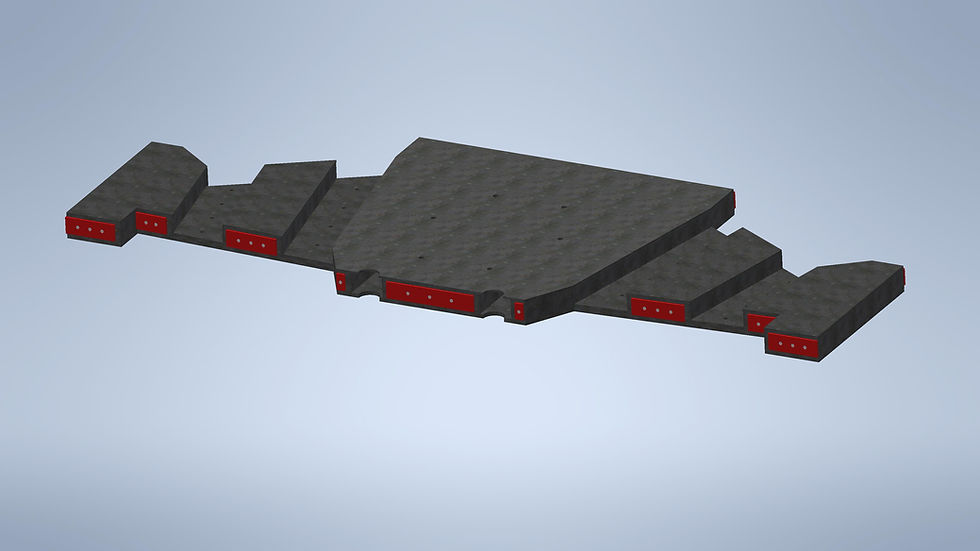

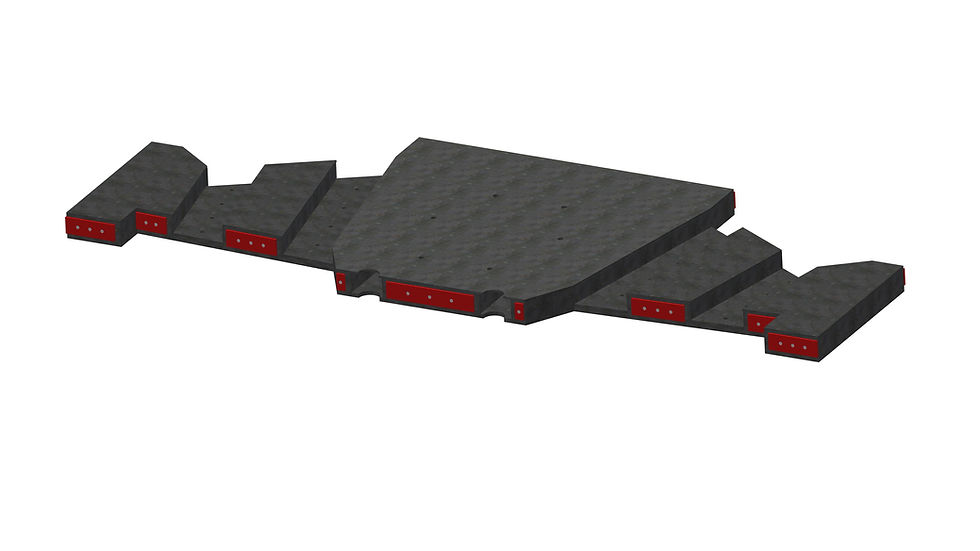

Work in Process Steel Pallets

Reducing cost by 70%

Saved customer expense by not having to build 26 new racks, reducing cost by 70%

INDUSTRY

Automotive

THE “ASK”

Toyota Motor Manufacturing Indiana had a part that went through a design change on the 26 previously fabricated pallets.

HOW IT’S USED

For stamping blanks in making a body part of a vehicle.

UNIQUE ABOUT THE SPECS

Due to the engineering change of the part that goes on this pallet, we had to take the existing pallet and retrofit and rework it. We retrofitted all 26 pallets to match the new part design.

HOW WE HELPED THE CUSTOMER

We did an analysis to ensure it was worthwhile to do the refurbishing. Often times, there is so much damage or wear that it would cost more to refurbish. In this case, it made sense.

CAPABILITES

-

- Refurbish

STEPS

-

- Confirm Scope

- Disarm Old Plastic

- Hand Plasma

- Hand Grind Plasma

- Plasma Cut New Steel

- Saw New Plastic

- Machine New Steel & Plastic

- Weld in New Steel

- Paint New Steel

- Assemble New Plastic

- Stencil

WHAT PEOPLE ARE SAYING

“I would like to recommend…for further business within Toyota North America, particularly related to packaging. I have been using [them] for years, primarily in the construction of …blank pallets. They …always deliver a quality product on time. In the rare occasions that I have had an issue with their product they have been quick to remedy the situation. …communicates well and gives regular schedule updates during their build. …They also have been helpful in providing recommendations on how to improve the products I have had them working on…would be a great addition as a potential fabricator for these pallets.” Colleague, Stamping Toyota Motors Manufacturing, Kentucky