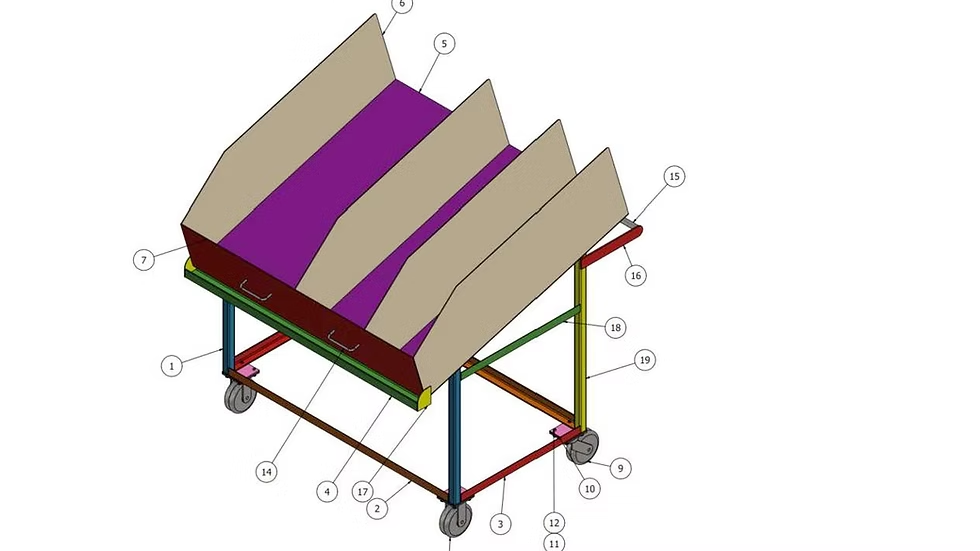

Work in Process Carts

Within 10 days, expedited design to production & delivery

INDUSTRY

Electric

THE “ASK”

Schneider Electric asked that we duplicate their existing work in process carts, and add push handles to make them easier to use on the floor. Also, we had a time constraint of two-weeks to turn the carts around. They were ramping up their weekend shift and needed more carts.

WHAT’S UNIQUE ABOUT THE SPECS

Separation of parts in each of the openings while ensuring that the parts were conveniently placed close to one another. This allowed the worker to load part a, b and c in a segregated fashion but within reach, sequentially.

HOW WE HELP THE CUSTOMER

We had no prints. We needed to get creative by taking field measurements and reverse engineering the pieces. We visited to do “go and sees” to understand the improvements needed. We were able to simplify the process by ordering the casters from the vendor and assembling.

CAPABILITIES

-

- Refurbish

- Reverse Engineer

STEPS

-

- Confirm Scope

- Disarm old plastic

- 3D Model

- Confirm Design

- Manufacture Prints

- Saw Cut

- Machine

- Plasma Burn

- Weld

- Assemble

WHAT PEOPLE ARE SAYING

“Valence provides excellent service, price and expertise. No matter the project size, complexity, or deadline, they have risen up to the challenge and provided results that were beyond expatiation. This company will always be my first call for future projects.” R. Havel, Manufacturing Engineer Schneider Electric