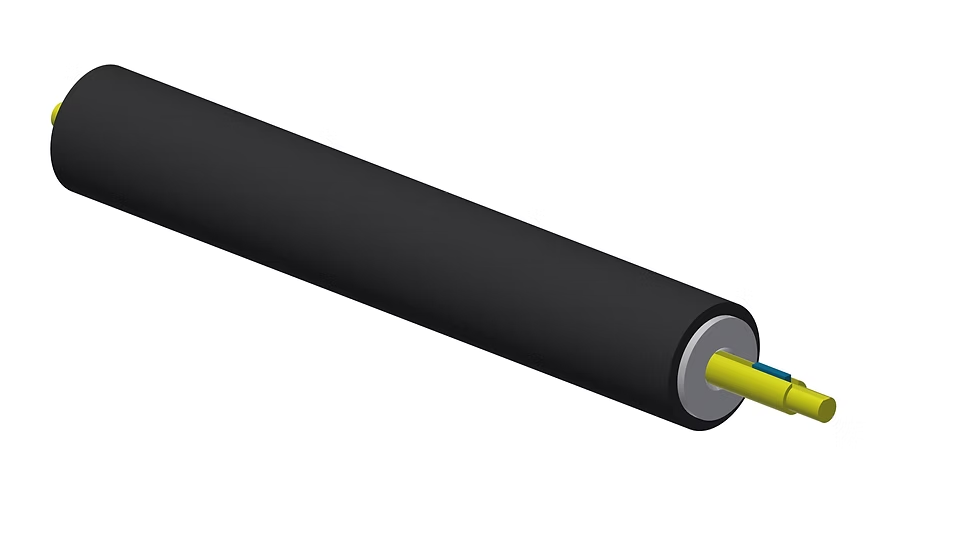

Conveyor Rollers

Replacement of chain-driven rollers, rolling blanks from one process to another

__

Reducing cost by 75%

Reverse engineered from worn out sample, due to not having prints

INDUSTRY

Electric

THE “ASK”

Schneider Electric had conveyor rollers that were worn out. Their OEM would not make any replacements because they were requesting a smaller batch of rollers–basically just the componentry, rather than recreating the entire conveyer line system. They asked that we reverse engineer the rollers.The second request was a rack that holds shaker trays. This is where they collect bi-product from the stamping operation.

WHAT’S UNIQUE ABOUT THE SPECS

We sourced and fabricated the componentry including sourcing urethane coating and grinding. It’s what provides the grip to move the pieces across it. We turned the rod and end caps on the lathe, cutting the cooling to secondary source for urethane coating and grinding.

HOW WE HELP THE CUSTOMER

Reverse engineered from worn out sample, due to not having prints.

CAPABILITIES

- Reverse Engineer

STEPS

- Confirm Scope

- “Go & See” Daily Application

- Reverse Engineer

- 3D Model

- Confirm Design

- Manufacture Prints

- Saw Cut

- Machine

- Urethane Coat & Grind

- Assemble

WHAT PEOPLE ARE SAYING

“Valence provides excellent service, price and expertise. No matter the project size, complexity, or deadline, they have risen up to the challenge and provided results that were beyond expatiation. This company will always be my first call for future projects.”

R. Havel, Manufacturing Engineer

Schneider Electric